Architecture & British Climate

How much water protection do you need for your external wall system?

Why you should think about the right membrane for your project.

Breather membranes play a key role within the building envelope. Their vapour permeability facilitates the release of excess moisture vapour into the exterior, helping to keep internal wall roofing structures dry and protect the condition of insulation layers. They can also serve a valuable purpose as a line of defence against water penetration during the construction stage and the lifetime of the completed building, but the importance of this function – and the level of performance required to fulfil it – can depend on the size, design and location of the building in question. A membrane which proved to be adequate for one project could prove to be wholly inadequate for another project.

The nuances of water protection from building membranes are often overlooked or misunderstood. It’s a common problem within the construction industry and more clarity on the subject would extend the lifespan of many future constructions, avoiding the need for expensive remediation work further down the line.

How is water resistance assessed in breather membranes?

A breather membrane’s ability to resist the passage of water through a vertical wall system is measured by its watertightness. The current code for Breather Membranes is BS EN 13859-2 which has superseded code BS4016 :1997. BS EN 13859-2 lists three classifications in descending order of watertightness: W1, W2 and W3.

Which water tightness ratings are suitable for breather membranes?

W3 is not used for wall panels. To comply with BS 13859-2 a membrane should carry either a Class W1 or W2 resistance to water penetration. The Structural Timber Association (STA) issued an Advice Note which states that a membrane with a W2 classification is suitable for use in the majority of applications where continuous rainscreen cladding is used without gaps such as masonry or render board. The manufacturer should confirm that a Class W2 membrane achieves a minimum of zero leakage in the aged condition to BS 13859-2.

However, the level of acceptance for W2 under BS EN 13859-2 is often subject to confusion as the test and water leakage acceptance rates differ from the testing used for the superseded BS 4016. Having reviewed the differing EN and BS test methods, the STA recommends that breather membranes achieve zero leakage under the EN test as a minimum value.

During the service life of the building wall, STA recommends Class W1 to BS EN 13859-2 for all projects and cladding types specifically for projects with open jointed façade cladding or leaky cladding and Class W2 to BS EN 13859-2 for projects with continuous rainscreen cladding types.

With its higher test credentials, a W1 membrane provides better protection of sheathing / frame materials during the construction process than a W2 membrane.

WHAT TEST CRITERIA APPLY TO W1 AND W2?

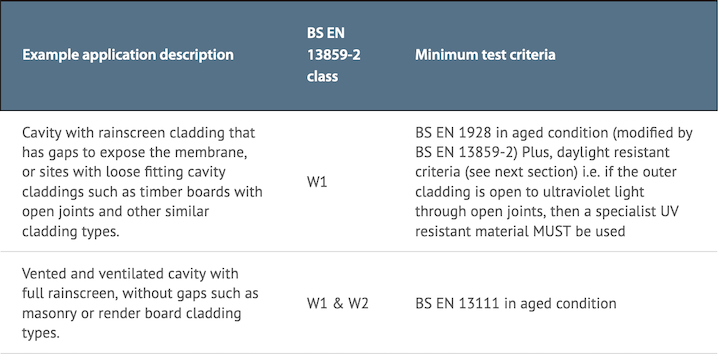

The following table from the STA Advice Note provides the minimum test criteria:

An important element of the test criteria is the performance of the membrane in aged condition.

When determining a suitable membrane classification for a building, one of the most commonly overlooked factors are the local conditions.

Class W1 is recommended as good practice when a building occupies a location that is known to be exposed to high winds and driving, persistent rain. These locations are typically found on high-altitude exposed sites and westerly coastal sites in England, Ireland, Wales and Scotland. Cliff or sea fronting locations are particularly exposed. In such cases, a membrane that achieves W1 aged water penetration resistance is recommended to be used with full rainscreen cladding, in conformance to BS 13859-2.

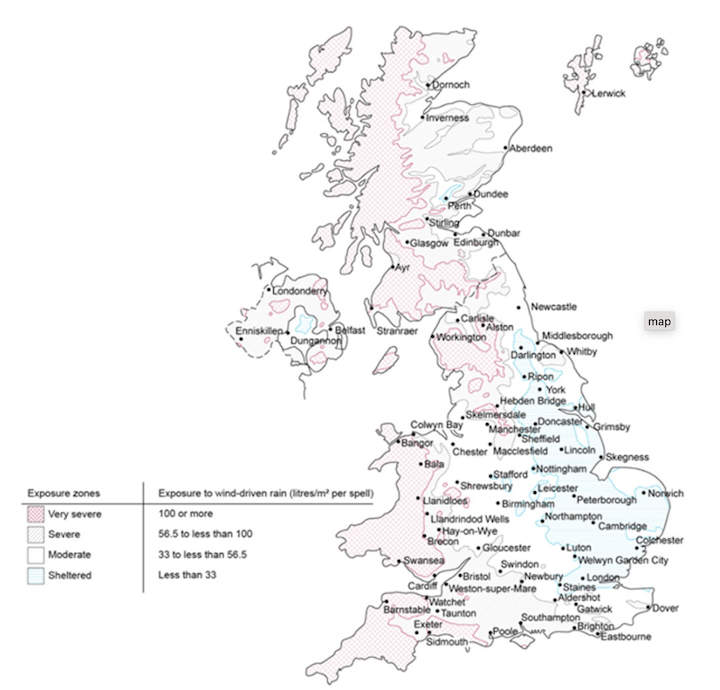

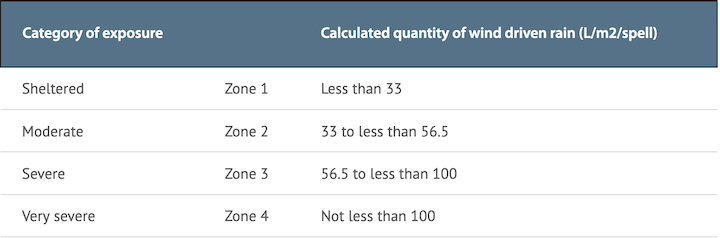

BS 8104 recommends the use of the local spell index method to assess the resistance of a wall to rain penetration. The exposure categories in terms of wall spell indices are given in the table below using the local spell index. They should not be regarded as exact as local circumstances or experience may require adjustments to be made. When an assessment produces an intermediate index, the designer should utilise local knowledge, topography and experience to determine the most appropriate exposure index.

MAP OF RAIN EXPOSURE

In general, any area within 30 miles of a west facing coastline is considered to be in a severe exposure area. However, localised effects on any site must also be taken into consideration. Exposure gradings and local knowledge should be referred to when discussing design requirements. Further reference to BS 8104 is advisable to ascertain localised effects.

Should you take into account the height of a building?

NHBC Standards – Section 6.1.6 references how site-specific calculations can be made using BS 8104 ‘Code of practice for assessing exposure of walls to wind-driven rain’ which takes into account wall heights.

This document is available online:

Code of practice for assessing exposure of walls to wind-driven rain

OTHER KEY PERFORMANCE REQUIREMENTS FOR BREATHER MEMBRANES

Breathability

Although BS 4016 has been withdrawn and replaced, there are some aspects of its specification that remain useful for designers. The new standard references test standards but does not contain performance requirements for the breathability of the breather membranes. Condensation risk calculations should model using the exact materials being used in the external wall, utilising the manufacturer’s test data. The Timber Research and Development Association (TRADA) recommends that “designers follow BS 4016 regarding moisture vapour resistivity of breather membranes for walls. Deviation for this moisture vapour resistance performance is permitted only if interstitial condensation risks are assessed using specific material properties and the results are favourable.”

The maximum water vapour resistance of 0.6 MNs/g set out in BS 4016 is still very much used for façade breather membranes.

Fire safety

In a post-Grenfell construction sector, fire safety is also a critical performance quality. Laws introduced in response to Grenfell require an external wall construction over 18m to have a minimum Euroclass A2-s1,d0 fire safety rating – denoting limited combustibility – but breather membranes installed behind the cladding are subject to less stringent standards. They are currently exempt from being A1 or A2-s1, d0. The minimum Euroclass rating required for a breather membrane is B-s3,d0. However, it is considered best practice to install a breather membrane that meets the Euroclass A rating in line with the standards required for cladding and other external wall elements.

UV resistance

UV resistance is also an important consideration in certain buildings. Most breather membranes are manufactured from polyolefins which can be affected by long-term exposure to UV. Open jointed façade cladding, with gaps that expose the membrane and the passage of ultraviolet light and weather, require a Class W1 resistance to water penetration and confirmation that the membrane has been tested to a minimum of 5000 hours of accelerated UV ageing with an energy minimum of 812MJ/m2 to BS 13859-2.

Download Whitepaper

>>>Please download our latest Whitepaper with full technical documentation for realisation of external wall systems completly in Euroclass A2 with Stamisol Safe One façade breather membranes.

Download

Tech Guide

>>> Please download our Technical Guide Stamisol Safe One for full information on construction models and what you should care about design and planning.

Download Technical Guide Stamisol Safe One